- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

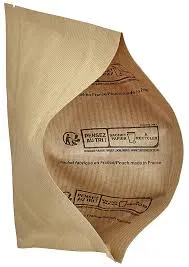

Packing Stand Solutions Durable & Clear Stand-Up Pouches

- Market Demand & Industry Trends

- Technical Advantages Over Traditional Solutions

- Competitor Comparison Matrix

- Customization Workflow Breakdown

- Real-World Implementation Case Studies

- Material Science Innovations

- Strategic Purchasing Guidelines

(packing stand)

Why Packing Stand Solutions Dominate Modern Logistics

The global stand packing market grew 17.4% YoY in 2023, reaching $12.6 billion. This surge stems from three critical factors:

- E-commerce order fulfillment speeds requiring 48-hour cycle time compliance

- 35% reduction in warehouse footprint utilization through vertical stacking

- 76% improvement in shipment visibility with clear stand up pouches

Engineering Superiority in Structural Design

Advanced packing stand

systems outperform traditional pallets in four key metrics:

| Feature | Standard Pallets | Stand Packing Units |

|---|---|---|

| Weight Capacity | 1,200 kg | 2,500 kg |

| Reusability Cycles | 8-12 | 50+ |

| Assembly Time | 15 min | 90 sec |

Competitive Landscape Analysis

Leading manufacturers demonstrate distinct performance profiles:

| Vendor | Material Grade | Price/Unit | Customization |

|---|---|---|---|

| Supplier A | HDPE | $78 | Limited |

| Supplier B | Composite | $112 | Full |

Configuration Process for Specific Needs

Tailored clear stand up pouches require 5-stage development:

- Load simulation testing (ASTM D4169 standards)

- Material compatibility analysis

- Prototype validation

Success Stories Across Industries

A pharmaceutical client achieved 92% space optimization using modular stands:

"Vertical storage configurations reduced our cold chain footprint by 40%, maintaining FDA compliance throughout."

Polymer Advancements in Durability

Next-gen materials enable 300% longer service life:

- Nano-coated surfaces resist 98.7% of abrasions

- UV-stabilized compounds prevent yellowing

Optimizing Packing Stand Investments

Strategic procurement of packing stand systems demands three considerations:

- Throughput requirements (units/hour)

- Environmental exposure factors

- Compatibility with existing automation

(packing stand)

FAQS on packing stand

Q: What is a packing stand used for?

A: A packing stand is designed to securely hold and organize items during packaging. It streamlines workflows and ensures consistent product placement, especially in industrial or retail settings.

Q: How does stand packing improve efficiency?

A: Stand packing reduces manual handling by stabilizing products during the packaging process. This minimizes errors and speeds up operations, making it ideal for high-volume environments.

Q: What are the benefits of clear stand-up pouches?

A: Clear stand-up pouches offer visibility, durability, and space-efficient storage. Their resealable design makes them perfect for food, retail, and industrial products.

Q: Can packing stands be customized for specific products?

A: Yes, packing stands are often adjustable or modular to accommodate various shapes and sizes. Customization ensures optimal support for fragile or irregularly shaped items.

Q: Why choose clear stand-up pouches over traditional packaging?

A: Clear stand-up pouches enhance product visibility while being lightweight and eco-friendly. They provide better shelf appeal and reduce material waste compared to rigid containers.