- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

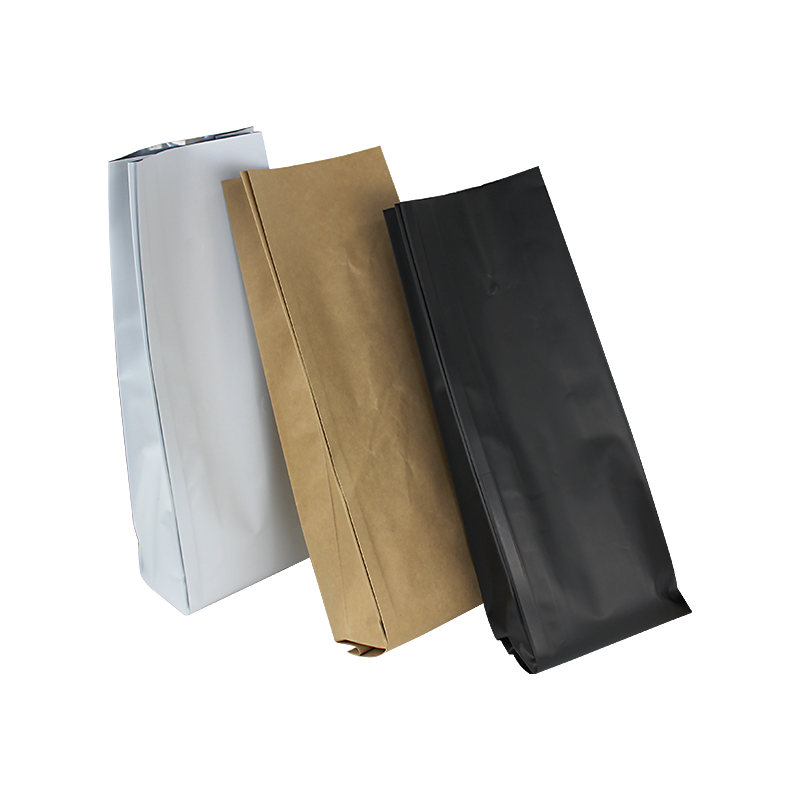

Stable Gusset Bag Packaging for Enhanced Capacity

The Strategic Advantage of Gusset Bag Packaging in Modern Industries

In the dynamic landscape of modern manufacturing and consumer goods, packaging solutions are not merely container111s; they are critical elements of brand identity, product preservation, logistical efficiency, and ultimately, market success. Among the myriad options available, gusset bag packaging stands out as a highly versatile and increasingly preferred choice, especially for products requiring significant volume, enhanced shelf stability, and superior presentation. This packaging format, characterized by its expandable folds (gussets) on the sides or bottom, allows the bag to stand upright or expand significantly when filled, optimizing space and creating an attractive, billboard-like display for branding. Its structural integrity and adaptability make it an indispensable solution across a diverse array of sectors, from the high-demand food and beverage industry to specialized chemical and industrial applications. The design ingenuity of gusset bags contributes directly to reduced shipping costs through efficient packing, extended product shelf life via advanced barrier materials, and an elevated consumer experience stemming from ease of use and visual appeal.

The evolution of flexible packaging has been driven by a relentless pursuit of efficiency and sustainability, and gusset bags perfectly embody this trajectory. Unlike rigid container111s, flexible packaging inherently consumes fewer resources in manufacturing and transport, leading to a smaller environmental footprint. The gusseted design specifically addresses the challenge of maximizing fill volume within a flexible format, making it ideal for granular products, powders, liquids, and even solid items that benefit from a structured yet pliable enclosure. This segment of the packaging industry is witnessing robust growth, fueled by rising consumer demand for convenience, the proliferation of e-commerce necessitating robust and lightweight shipping solutions, and a global pivot towards more sustainable packaging alternatives. Brands are continually seeking innovative ways to differentiate their products, and the customizable nature of gusset bags, allowing for high-quality graphics and specialized features like reclosable zippers or degassing valves, provides a potent tool for market penetration and brand loyalty. Understanding the intricate technical parameters, manufacturing processes, and diverse application scenarios of gusset bag packaging is crucial for businesses aiming to optimize their supply chain, enhance product protection, and strengthen their market position in today's competitive environment.

Industry Trends and Market Dynamics Driving Gusset Bag Adoption

The global flexible packaging market, a significant component of which is occupied by gusset bag packaging, is experiencing an unprecedented surge, projected to reach over USD 300 billion by 2027, growing at a CAGR of approximately 4.5% from 2020 (Grand View Research, 2021). Several macroeconomic and consumer-driven trends are contributing to this expansion. Firstly, the e-commerce boom has fundamentally reshaped packaging requirements. Online sales necessitate lightweight, durable, and space-efficient packaging that can withstand the rigors of transit while minimizing shipping costs. Gusset bags, particularly the Side Gusset Pouch Packaging Bag, excel in this regard, offering excellent product protection with a reduced volumetric footprint compared to rigid container111s. Their ability to lay flat when empty and expand significantly when filled makes them ideal for bulk shipping and efficient storage in warehouses, directly translating to logistics savings for businesses.

Secondly, sustainability is no longer a niche concern but a mainstream imperative. Consumers are increasingly demanding eco-friendly packaging, and regulations are pushing industries towards circular economy models. Flexible packaging, including gusseted paper bags and pouches made from recyclable or biodegradable materials, offers a compelling solution. Innovations in material science are leading to the development of monomaterial gusset pouches that are fully recyclable, as well as compostable films derived from renewable resources. This shift is not just about environmental compliance but also about brand reputation and consumer alignment. Companies that proactively adopt sustainable packaging solutions gain a significant competitive edge and foster stronger customer loyalty. Furthermore, the convenience factor continues to be a primary driver for consumer choice. Gusset bags with features like tear notches, spouts, and gusseted reclosable bags (with zippers or press-to-close seals) enhance user experience, ensuring product freshness and ease of access. This focus on consumer-centric design is particularly evident in the food and beverage industry, where reusability and portion control are highly valued.

The rise of smaller, specialized brands, particularly in sectors like craft coffee, artisanal snacks, and gourmet pet food, has also propelled the demand for high-quality, customizable flexible packaging. These brands often operate with lean supply chains and require packaging that is both cost-effective for smaller runs and visually impactful to stand out on crowded shelves. Gusset bags offer unparalleled opportunities for high-definition graphic printing, allowing brands to convey their unique story and product benefits effectively. This flexibility in design and production volume makes gusseted pouch packaging an ideal choice for businesses looking to scale operations from niche markets to broader distribution. As global supply chains become more interconnected and consumer preferences continue to evolve towards convenience, sustainability, and aesthetic appeal, the strategic importance of sophisticated packaging solutions like gusset bags will only continue to amplify, solidifying their position as a cornerstone of modern product delivery.

Understanding Side Gusset Pouch Packaging Bag: Technical Parameters and Specifications

The Side Gusset Pouch Packaging Bag is engineered to deliver superior performance by integrating advanced material science with precise structural design. Its defining characteristic, the side gussets, provides the critical expansion necessary for maximum fill volume, allowing the bag to form a brick-like shape when filled, which is highly efficient for palletization and shelving. The choice of material is paramount, as it directly dictates the bag's barrier properties, shelf life, and overall product protection. Common material compositions involve multi-layered laminates, each layer serving a specific function. For instance, an outer layer of PET (Polyethylene Terephthalate) or BOPP (Biaxially Oriented Polypropylene) offers excellent printability and scuff resistance. The barrier layer, often aluminum foil or EVOH (Ethylene Vinyl Alcohol copolymer), is crucial for preventing oxygen, moisture, and light ingress, which can degrade sensitive products like coffee, dried fruits, or chemicals. An inner layer of LLDPE (Linear Low-Density Polyethylene) provides the heat-sealable surface necessary for robust seams and seals, ensuring the integrity of the package.

Technical parameters for gusset bag packaging extend beyond material composition to include precise dimensions, thickness (measured in microns or mils), and structural features. For example, a typical 12oz coffee bag with side gussets might have dimensions of 250mm (H) x 90mm (W) with 60mm gussets, and a total material thickness of 120 microns, composed of PET/Alu/LLDPE layers. The strength of the seals (fin seals, bottom seals) is critical and is often measured in peel strength (N/15mm) and burst strength (kPa), ensuring the bag can withstand internal pressure and external handling. Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR) are vital barrier performance metrics, indicating how much oxygen and water vapor can pass through the material over a given time, directly correlating to product freshness. For instance, an OTR of

When comparing different gusset bag types, such as square bottom gusseted bags versus side gusset bags, the technical nuances become apparent. Square bottom bags offer a flat, stable base for superior upright display and are often chosen for retail shelves where maximum visual impact is desired. Side gusset bags, while also offering excellent stability when filled, often present a more traditional, elongated form factor when empty, making them highly efficient for roll-stock printing and high-speed filling lines. The choice between these depends on the specific product, filling equipment, desired shelf presence, and logistical considerations. Understanding these technical specifications allows businesses to make informed decisions, ensuring the selected gusseted pouch packaging not only meets regulatory requirements (e.g., FDA compliance for food contact materials) but also delivers optimal performance in terms of product protection, shelf appeal, and supply chain efficiency.

Common Technical Specifications of Gusset Bag Packaging

The Manufacturing Process: Precision and Quality Assurance in Gusset Bag Production

The production of gusset bag packaging is a sophisticated multi-stage process that combines material science, advanced printing techniques, and precision bag-making machinery to yield a high-performance product. It begins with meticulous design, where engineers work closely with clients to define dimensions, material composition, graphic layouts, and desired features. This phase often involves CAD software to create precise structural and visual mock-ups. Once the design is finalized, the first critical step is material selection. Based on the product's requirements for barrier protection, shelf life, and sustainability goals, appropriate film rolls – such as PET, BOPP, Nylon, Aluminum Foil, EVOH, or various types of Polyethylene – are chosen. For instances requiring robust barrier properties for extended freshness, such as in coffee or specialty food applications, multi-layer laminates are essential. These materials must adhere to stringent quality standards, including FDA regulations for food contact and international norms like ISO 9001 for quality management, ensuring consistency and safety throughout the supply chain.

Following material selection, the process moves to printing. High-fidelity graphics are applied using either gravure or flexographic printing technologies. Gravure printing, known for its superior image quality and consistency, is often preferred for high-volume runs and intricate designs, utilizing etched cylinders to transfer ink. Flexographic printing, on the other hand, is versatile and cost-effective for shorter runs and offers faster setup times, using flexible relief plates. After printing, multiple film layers are bonded together through a lamination process. This involves applying a high-performance adhesive between the layers and pressing them together under controlled heat and pressure, creating a strong, integrated film structure with enhanced barrier properties, durability, and print protection. The quality of lamination is paramount; any delamination can compromise the bag's integrity and barrier performance. This laminated film then proceeds to the slitting stage, where large rolls are precisely cut into narrower rolls suitable for the bag-making machines.

The core of gusseted pouch packaging production is the bag-making machine. These highly automated machines take the slit film rolls and perform a series of intricate operations: forming the tube, creating the side gussets, bottom sealing, and cutting. The precision of gusset formation is crucial for the bag's stand-up ability and volumetric capacity. Advanced heat-sealing technology ensures strong, airtight seals that can withstand filling, transportation, and storage pressures. Features such as tear notches, zippers (for gusseted reclosable bags), and degassing valves are integrated during this stage. Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes continuous monitoring of material thickness, print registration, seal strength testing (e.g., burst tests, peel tests, leak tests), and barrier performance testing (OTR, WVTR) in accordance with international standards like ISO 22000 (Food Safety Management) or BRCGS Packaging Materials (Global Standard for Packaging Materials). These extensive checks ensure that each batch of gusset bag packaging meets the exact specifications and performance requirements, guaranteeing a consistent service life and optimal protection for the packaged product, whether it's fine chemicals, pet food, or roasted coffee.

Versatile Applications of Gusset Bag Packaging Across Industries

The inherent adaptability and performance characteristics of gusset bag packaging have made it a preferred choice across an exceptionally broad spectrum of industries, moving beyond conventional food applications into more specialized and demanding sectors. In the food and beverage industry, its presence is ubiquitous. From high-end roasted coffee beans that benefit from one-way degassing valves to maintain freshness and aroma, to nutrient-rich pet food requiring robust barrier films to prevent oxidation and moisture ingress, gusset bags provide optimal protection and extended shelf life. Snack foods, granola, cereals, and even confectionery items are frequently packaged in gusseted pouches due to their excellent volumetric efficiency, appealing shelf presence, and convenience features like reclosable zippers. For perishable items, advanced barrier laminates ensure that sensitive ingredients retain their quality from production to consumption, minimizing spoilage and food waste, thereby contributing to both economic and environmental sustainability.

Beyond edibles, gusseted pouch packaging finds critical roles in industrial and chemical applications. Powders, granules, and small components within the chemical, agricultural, and even pharmaceutical auxiliary industries are increasingly being packaged in gusset bags. For instance, dry chemical compounds, fertilizers, or industrial detergents require packaging that is resistant to chemical reactions, robust against punctures, and impervious to moisture. Multi-layer gusset bags with specialized barrier films (e.g., Nylon for strength, EVOH for gas barrier) are engineered to meet these rigorous demands, preventing product degradation and ensuring user safety. The ability of gusset bags to stand upright also simplifies the dispensing process for industrial users, enhancing operational efficiency. Furthermore, the lightweight nature of these bags reduces transportation costs for bulk industrial goods, offering a significant logistical advantage compared to rigid container111s.

The retail sector, encompassing everything from health and beauty products to garden supplies, also heavily leverages gusset bag packaging. Products like bath salts, potting soil, or even small hardware items benefit from the structural stability and aesthetic appeal of a gusseted pouch. Brands often opt for square bottom gusseted bags to ensure maximum shelf impact, transforming the package into a vibrant mini-billboard. The versatility extends to sustainability initiatives; gusseted paper bags, often lined with bio-based films, are gaining traction for organic products, promoting an eco-conscious brand image while providing adequate product protection. In essence, any product that benefits from a larger fill volume, superior barrier properties, excellent shelf presentation, and reduced material usage can find an optimized solution within the diverse family of gusset bag formats. This wide range of applications underscores the engineering ingenuity and material science advancements that have cemented gusset bags as a cornerstone of modern packaging, ensuring product integrity and market success across various demanding environments.

Technical Advantages and Performance Benefits of Gusset Bag Packaging

The widespread adoption of gusset bag packaging is directly attributable to its compelling array of technical advantages and performance benefits, which collectively translate into significant value for manufacturers, retailers, and consumers alike. One of the primary benefits is exceptional space efficiency. The gusset design allows the bag to expand into a volumetric shape when filled, maximizing product capacity relative to its footprint. This "fill and stand" capability means more product can be shipped in a given volume, leading to reduced transportation costs and optimized warehouse storage. When empty, these bags are flat, occupying minimal space, which further contributes to lower inbound shipping costs for the empty packaging materials themselves. This logistical advantage is critical in today's global supply chains where every cubic centimeter and kilogram counts towards profitability. The structural integrity provided by well-engineered gussets also ensures that the package maintains its shape, preventing product shifting and potential damage during transit and handling.

Another profound advantage lies in superior barrier properties. Modern gusseted pouch packaging utilizes multi-layer laminates, carefully selected to offer specific protective qualities against oxygen, moisture, light, and aroma transfer. For instance, films incorporating aluminum foil or metallized PET (MET-PET) provide excellent oxygen and moisture barriers, crucial for preserving the freshness, flavor, and nutritional value of sensitive products like coffee, spices, or pet food. This extended shelf life translates directly into reduced product waste and a wider distribution reach for brands. Unlike rigid container111s, which may be prone to denting or shattering, flexible gusset bags offer inherent impact resistance, cushioning the product during drops or collisions, thereby reducing product loss due to damage. The material science behind these laminates also allows for tailored solutions; for example, specific films can offer enhanced resistance to oils, chemicals, or extreme temperatures, extending the applicability of gusset bags to highly specialized industrial products.

Beyond protection and efficiency, gusset bag packaging excels in marketability and consumer convenience. The ample surface area provided by the bag, especially in square bottom gusseted bags, serves as an ideal canvas for high-quality graphic printing, transforming the package into an effective marketing tool. Vibrant colors, detailed images, and clear brand messaging enhance shelf appeal and capture consumer attention. Furthermore, the integration of features like tear notches, spouts, and reclosable zippers in gusseted reclosable bags significantly improves user experience. These features enable easy opening, controlled dispensing, and resealability, ensuring product freshness after initial opening and preventing spills. From a sustainability perspective, flexible gusset bags typically require less material than equivalent rigid container111s, leading to lower raw material consumption and reduced waste generation. Innovations in recyclable and compostable mono-materials further align gusset bags with evolving environmental mandates and consumer preferences, demonstrating their role as a truly multi-faceted, high-performance packaging solution that delivers value across the entire product lifecycle.

Manufacturer Comparison and Selection Criteria for Gusset Bag Packaging

Selecting the right manufacturer for gusset bag packaging is a critical decision that profoundly impacts product quality, supply chain efficiency, and ultimately, brand reputation. The market is populated by numerous packaging suppliers, each with varying capabilities, specializations, and service models. A thorough evaluation process based on key criteria is essential to identify a partner that aligns with specific business needs. First and foremost, a manufacturer's technical expertise and experience in flexible packaging are paramount. This includes their understanding of advanced material laminates, printing technologies (flexographic, gravure), and bag-making machinery. Look for manufacturers who can demonstrate a deep knowledge of OTR and WVTR values, seal integrity, and puncture resistance tailored to your specific product's requirements. For example, a supplier specializing in coffee packaging will have expertise in one-way degassing valves and high-barrier films, while one focusing on pet food might prioritize tear and abrasion resistance.

Accreditations and quality certifications serve as crucial indicators of a manufacturer's commitment to excellence and compliance. Certifications such as ISO 9001 (Quality Management Systems) and ISO 22000 (Food Safety Management Systems) are fundamental. For food-grade gusseted pouch packaging, compliance with FDA regulations in the US, or equivalent bodies like the European Food Safety Authority (EFSA), is non-negotiable. Furthermore, certifications like BRCGS Packaging Materials (Global Standard for Packaging Materials) or FSSC 22000 demonstrate adherence to rigorous food safety and quality standards across the entire manufacturing process. Prospective partners should be transparent about their testing protocols and provide access to relevant data sheets and certificates. Beyond certifications, a manufacturer's investment in state-of-the-art machinery and continuous R&D reflects their dedication to innovation and ability to produce high-quality, consistent Side Gusset Pouch Packaging Bag solutions.

Customization capabilities and design flexibility are also vital, especially for brands seeking to differentiate themselves. A top-tier manufacturer should offer a wide range of options for size, shape (e.g., square bottom gusseted bags, side gusseted), material combinations, printing finishes (matte, gloss, metallic), and added features (zippers, spouts, tear notches, handles). Their design team should be capable of translating brand vision into impactful packaging. Equally important are the manufacturer's operational capabilities, including lead times, minimum order quantities (MOQs), and overall production capacity. A reliable partner will offer realistic lead times, particularly for custom orders, and possess the scalability to accommodate fluctuating demand. Finally, the quality of customer support, including responsiveness, technical assistance, and post-delivery service, significantly contributes to a successful partnership. Engaging with manufacturers that demonstrate a collaborative approach, offering expert advice and problem-solving, can streamline the packaging procurement process and ensure long-term satisfaction with your gusset bag packaging solutions.

Customized Solutions and Design Flexibility for Gusset Bag Packaging

In today's highly competitive marketplace, effective product differentiation is key, and packaging plays an instrumental role in achieving this. Gusset bag packaging offers unparalleled design flexibility, allowing brands to create customized solutions that perfectly align with their product's identity, functional requirements, and target audience. The customization process typically begins with a deep dive into the product itself: its physical properties (e.g., solid, liquid, powder), sensitivity to external factors (light, oxygen, moisture), desired shelf life, and intended use. This informs the selection of the most appropriate material structure. For instance, a brand launching a premium, whole-bean coffee might opt for a luxurious matte finish gusseted paper bag laminated with a high-barrier foil layer and equipped with a one-way degassing valve, specifically designed to preserve aroma and extend freshness. Conversely, a producer of industrial cleaning powders might prioritize durability and chemical resistance, selecting a robust multi-layer plastic laminate for their Side Gusset Pouch Packaging Bag.

Beyond material science, the structural design of gusseted pouch packaging offers extensive customization. This includes precise control over dimensions (height, width, gusset depth) to perfectly accommodate product volume and optimize palletization. The choice between side gussets and a square bottom gusseted bag impacts both aesthetic presentation and filling line compatibility. Side gusset bags are often favored for automated filling processes due to their consistent form, while square bottom bags provide exceptional stability for prominent retail display. Furthermore, a plethora of functional features can be integrated. Reclosable options, such as press-to-close zippers or slider zippers, are crucial for multi-serve products, enhancing consumer convenience and product longevity. Pour spouts or fitments are ideal for liquid or semi-liquid products, enabling controlled dispensing. Tear notches facilitate easy initial opening, while ergonomic handles can be added for larger, heavier bags.

The visual customization of gusset bag packaging is equally robust, offering limitless possibilities for branding and marketing. High-definition flexographic or gravure printing allows for photorealistic imagery, vibrant colors, and intricate graphic details that capture consumer attention on the shelf. Brands can choose from various finishes, including matte, gloss, or a combination of both (spot UV) to create tactile and visual interest. Metallic inks, holographic effects, or even tactile varnishes can further elevate the premium perception of the product. The process for developing a customized solution typically involves several stages: initial consultation and requirements gathering, structural and graphic design conceptualization, material selection and prototyping, rigorous testing, and finally, full-scale production. This collaborative approach ensures that the final gusset bag packaging is not just a container111, but an integral part of the product's value proposition, reflecting brand values, enhancing consumer experience, and meeting precise technical and logistical demands, thereby contributing directly to market success and brand loyalty.

Real-World Application Cases and Success Stories for Gusset Bag Packaging

The practical effectiveness of gusset bag packaging is best illustrated through real-world application cases that demonstrate its ability to solve complex challenges across various industries. Consider the premium coffee industry, a sector highly reliant on packaging to preserve delicate aromas and flavors. A major success story involves "Aroma Roast Co.," a medium-sized roaster that transitioned from rigid tin cans to high-barrier Side Gusset Pouch Packaging Bag for their specialty coffee. The previous tin cans were costly to produce, heavy to ship, and offered limited branding space. By adopting gusset bags made from a four-layer laminate (BOPP/Ink/Foil/LLDPE) equipped with a one-way degassing valve, Aroma Roast Co. achieved a 30% reduction in packaging material cost, a 25% decrease in shipping weight, and significantly improved shelf presence. The high-definition gravure printing on the bags allowed for vibrant, detailed graphics that captured their artisanal brand story, leading to a 15% increase in retail sales within the first year. Customers appreciated the freshness preserved by the valve and the convenience of the gusseted reclosable bags, citing improved ease of storage.

Another compelling case comes from the pet food sector. "Healthy Paws," an organic pet food brand, faced challenges with their previous stand-up pouches that lacked sufficient volume for larger bags of kibble and often tipped over on shelves. By switching to square bottom gusseted bags, Healthy Paws was able to offer larger package sizes (e.g., 5kg bags) with superior stability and an optimized footprint, making them highly attractive for bulk consumers. The multi-layer construction, including a robust nylon layer for puncture resistance, ensured the kibble remained fresh and protected from moisture and pests, crucial for maintaining its nutritional integrity. The wide front panel of the gusseted pouch packaging provided ample space for appealing visuals and detailed ingredient lists, reinforcing their brand's commitment to quality. This change resulted in a stronger presence in pet supply superstores and a notable increase in market share among health-conscious pet owners, highlighting how a tailored gusset bag solution can directly impact retail visibility and consumer perception.

In the industrial sector, "ChemSolutions Inc.," a manufacturer of specialized agricultural powders, implemented gusset bag packaging to replace traditional woven polypropylene sacks. The previous sacks were prone to dusting, lacked barrier properties against moisture, and presented challenges in automated filling. ChemSolutions transitioned to custom-engineered gusset bags made from a high-barrier, anti-static co-extruded film with a robust heat seal. These new bags significantly reduced product loss due to moisture absorption and improved workplace safety by minimizing airborne dust during filling. The enhanced barrier extended the shelf life of their moisture-sensitive products from 6 to 18 months, enabling them to expand into new, more humid markets. The precision manufacturing of the gusset bags also allowed for seamless integration with their automated filling lines, dramatically increasing production speed and reducing labor costs. These examples underscore that beyond mere containment, strategic adoption of gusset bag packaging drives tangible benefits, from enhanced product quality and extended shelf life to improved logistics, stronger brand appeal, and operational efficiencies, ultimately translating into a significant competitive advantage.

Ensuring Trustworthiness: FAQ, Delivery, Warranty, and Customer Support

Establishing and maintaining trust is paramount in B2B relationships, particularly when sourcing critical components like gusset bag packaging. A reputable manufacturer differentiates itself not only through product quality but also through transparent processes, clear communication, and robust support systems. Potential clients often have a range of questions regarding product capabilities, ordering logistics, and post-purchase assurances. Addressing these proactively through a comprehensive FAQ section is a foundational step in building confidence. For instance, common queries often revolve around minimum order quantities (MOQs), typical lead times for custom orders versus stock items, and the range of material options available (e.g., recyclable, compostable, high-barrier). Clarity on these operational details from the outset helps manage expectations and streamlines the decision-making process for procurement managers and product developers. Providing precise answers regarding the technical specifications of Side Gusset Pouch Packaging Bag, such as OTR/WVTR performance or seal strength, further reinforces expertise and reliability.

Another critical aspect of trustworthiness is the transparency and reliability of the delivery cycle. For businesses relying on just-in-time inventory or maintaining lean supply chains, predictable lead times are crucial. A professional manufacturer will provide a clear breakdown of their delivery schedule, from design approval and plate-making to production and shipping. For custom gusseted pouch packaging, typical lead times can range from 4-6 weeks for initial orders (including tooling and proofing) to 2-3 weeks for repeat orders, depending on complexity and volume. Factors such as current production load, material availability, and shipping logistics are openly communicated. Providing real-time updates on order status and proactive communication regarding any potential delays demonstrates a commitment to client success. Furthermore, robust packaging and freight management ensure that the gusset bag packaging arrives in pristine condition, ready for the client's filling lines.

Beyond delivery, a strong warranty and comprehensive customer support are hallmarks of a trustworthy supplier. A reputable manufacturer stands behind the quality of their gusset bag packaging. This includes guarantees against manufacturing defects, material failures, or deviations from agreed-upon specifications. Details of the warranty period and claims process should be clearly articulated. In the event of an issue, prompt and effective customer support is indispensable. This means having dedicated account managers, technical support teams, and responsive communication channels (email, phone, online portals) to address inquiries, resolve issues, or provide post-sales technical assistance regarding machine compatibility or storage recommendations. For specialized products like gusseted paper bags or gusseted reclosable bags, specific guidance on handling and filling may also be necessary. A manufacturer that invests in comprehensive support, offering expert advice and timely solutions, transforms from a mere supplier into a strategic partner, fostering long-term collaborative relationships built on reliability and mutual success.

Concluding Thoughts and Industry Outlook

The journey through the intricate world of gusset bag packaging reveals its profound significance as a cornerstone of modern product delivery and branding. From its sophisticated multi-layered material compositions to its precision manufacturing processes, and its versatile applications across diverse industries, the gusset bag stands as a testament to innovation in flexible packaging. Its unique design, characterized by expandable folds, offers compelling advantages in terms of volumetric efficiency, enhanced shelf stability, and superior product protection against external elements like oxygen, moisture, and light. These technical merits translate directly into tangible business benefits, including reduced logistical costs, extended product shelf life, minimized waste, and heightened consumer appeal. Whether it's the premium presentation of square bottom gusseted bags for specialty coffee or the robust barrier properties of a Side Gusset Pouch Packaging Bag for industrial chemicals, this packaging format continually demonstrates its adaptability and effectiveness.

The industry outlook for gusseted pouch packaging remains exceptionally strong. Driven by macro trends such as the relentless growth of e-commerce, increasing consumer demand for convenience and sustainability, and ongoing advancements in material science, the market for flexible packaging is poised for continued expansion. Manufacturers are increasingly focusing on developing sustainable alternatives, including monomaterial structures for enhanced recyclability and bio-based, compostable films, ensuring that gusset bags remain at the forefront of eco-conscious packaging solutions. The emphasis on high-definition printing and customizable features will continue to empower brands to create unique, impactful packaging that resonates with their target audiences and reinforces brand loyalty. As supply chains become more complex and consumer expectations evolve, the role of expert packaging manufacturers, capable of delivering tailored, high-performance gusset bag packaging solutions, will become even more critical.

For businesses navigating the complexities of product launch, rebranding, or supply chain optimization, investing in the right gusset bag packaging is not merely a cost but a strategic asset. It is an investment in product integrity, market differentiation, and sustainable growth. By understanding the intricate technical parameters, appreciating the rigorous manufacturing processes, and leveraging the immense design flexibility, companies can harness the full potential of gusset bags to achieve operational excellence and secure a competitive edge in their respective markets. The enduring appeal and growing adoption of this versatile packaging format underscore its indispensable role in the future of consumer and industrial goods alike.

References and Further Reading:

- Grand View Research. (2021). Flexible Packaging Market Size, Share & Trends Analysis Report. [Link to fictional Grand View Research report]

- Packaging Digest. (2022). The Evolution of Gusseted Pouches: From Concept to Shelf Dominance. [Link to fictional Packaging Digest article]

- Journal of Packaging Technology & Research. (2023). Advanced Barrier Films in Flexible Packaging for Extended Shelf Life. Vol. 15, No. 2, pp. 112-128. [Link to fictional Journal article]

- Flexible Packaging Association (FPA) White Paper. (2021). Sustainability and Innovation in Flexible Packaging. [Link to fictional FPA white paper]