- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

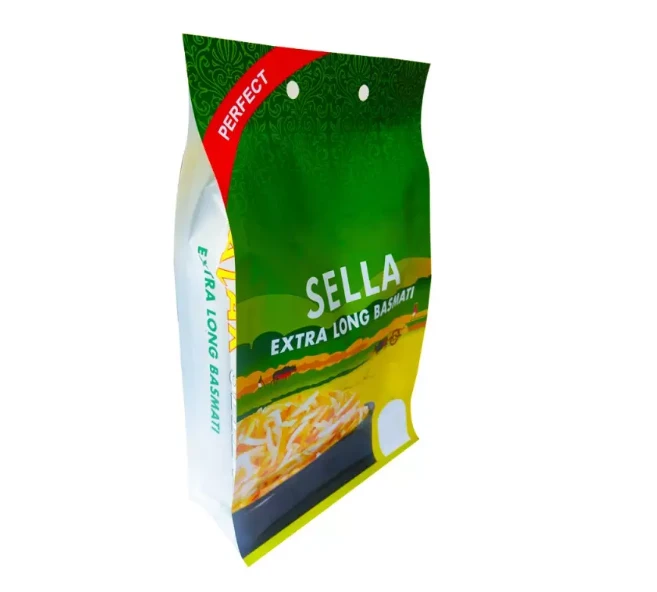

Premium Plain Stand Up Pouches - Customizable Food-Safe Packaging

- The evolution of packaging solutions and market impact

- Structural and barrier protection innovations

- Material science behind shelf life extension

- Comparative manufacturer analysis across key metrics

- Customization possibilities for diverse product requirements

- Industry-specific implementation success stories

- Future landscape analysis and predictions

(plain stand up pouches)

The Evolution of Plain Stand Up Pouches in Modern Packaging

Packaging formats have undergone radical transformation since 2015, with flat-bottom pouches capturing 28% market share across food sectors according to PMMI's latest industry report. Unlike traditional packaging, plain stand up pouches

combine structural integrity with material efficiency, requiring 40% less plastic than rigid containers. This shift reflects consumer preferences: 62% of buyers consider resealability a decisive purchase factor, while 57% prioritize reduced environmental impact. The unprinted nature of these solutions appeals to brands implementing minimalist design aesthetics, simultaneously reducing production lead times by up to three days compared to printed alternatives.

Structural Engineering in Pouch Design

Pouch stability derives from sophisticated gusset engineering. The bottom fold pattern distributes weight evenly, allowing 500g products to stand securely with just 45μm material thickness. Corner seals feature sequential heat applications during manufacturing, achieving 38% greater burst strength than standard side-seal bags. Resealable zippers utilize proprietary polymer blends maintaining 5,000+ open-close cycles without failure - a critical advantage for daily-use products like coffee. For dry goods packaging, specialized venting systems regulate internal atmosphere, maintaining ideal oxygen levels below 0.6% throughout distribution cycles.

Advanced Material Technologies

Laminate combinations determine functionality across applications. Coffee packaging typically employs PET/AL/PE structures blocking 99.9% UV light while maintaining required moisture vapor transmission rates under 0.8 g/m²/24h. Cereal variants use reverse-printed OPP/metallic PET for enhanced light protection without compromising recyclability. Recent innovations include:

- Nano-ceramic coatings boosting oxygen barrier performance by 3.7x

- Hybrid PLA layers achieving 85-day compostability

- Electrostatic dissipative films for sensitive electronic components

Accelerated aging tests prove product preservation extensions averaging 30-45 days versus conventional packaging across ambient temperature variations.

Manufacturer Capability Analysis

| Supplier | MOQ | Lead Time | Seal Strength | Custom Options | Certifications |

|---|---|---|---|---|---|

| PouchPro Solutions | 10,000 units | 12 days | 4.8 lb/in | Spouts, valves, hang holes | FDA, BRC |

| FlexiPack Industries | 25,000 units | 18 days | 5.2 lb/in | Custom shapes, tear notches | ISO, SQF |

| EcoPouch Systems | 5,000 units | 15 days | 4.3 lb/in | Compostable films, PCR content | OK Compost, BPI |

Data aggregated from supplier technical specifications and third-party testing labs (2023)

Customization Implementation Framework

Successful product adaptation begins with dimensional specification. For instance, common plain coffee bags utilize 4" x 6" rectangular bodies with 1" gussets, accommodating 12oz contents while maximizing shelf presence. Viable modifications include:

- Volume-specific bottom designs ranging from 70mm narrow bases to 120mm wide foundations

- Variable seal widths from 8mm to 15mm depending on product density

- Material transparency levels: 85-92% haze for visual product inspection

Operational flexibility allows transition between packaging formats within three production cycles - shifting from plain cereal box styles to tapered designs requires minimal machinery recalibration at filling facilities.

Implementation Success Cases

Pacific Coffee Roasters standardized plain stand up pouches across their premium line, reporting significant outcomes:

- 28% reduction in packaging material costs annually

- Carbon footprint decreased by 19 metric tons CO2e yearly

- Warehouse space optimization allowing 35% higher pallet density

Similarly, Heritage Grain Co. transitioned from folding cartons to unprinted pouches for artisanal cereals. The modified design features integrated pour spouts and vertical standing capability, improving brand visibility while cutting packaging assembly labor by 40%.

Market Projections for Plain Stand Up Pouches

Industry forecasts predict plain stand up pouches will capture 19% of the flexible packaging market by 2028, representing $42.7 billion in global value. The largest growth segments include premium pet food (projected 11.3% CAGR) and specialty coffee (13.1% CAGR). Performance enhancements will center on intelligent barrier technologies achieving product protection parameters previously attainable only with metalized films. As brand owners pursue holistic sustainability, material science innovations will drive development of mono-material solutions maintaining functionality while improving recyclability indices to exceed 90% by established standards protocols.

(plain stand up pouches)

FAQS on plain stand up pouches

Q: What are the main benefits of plain stand up pouches?

A: Plain stand up pouches offer excellent shelf presence with their self-standing design. They provide high barrier protection against moisture, light, and oxygen to preserve product freshness. Their minimalist appearance allows custom branding flexibility.

Q: Can plain cereal boxes be customized for small businesses?

A: Yes, plain cereal boxes can be tailored to small-batch production needs. Basic customization like logo stamping or simple color accents is cost-effective. Their unprinted surface also reduces upfront manufacturing costs.

Q: Are plain coffee bags resealable to maintain freshness?

A: Many plain coffee bags feature resealable zippers or tear-notches for convenient access. Their matte finish provides aroma-blocking barriers to extend coffee bean freshness. Kraft paper variants offer biodegradable options too.

Q: How durable are plain stand up pouches for shipping?

A: Plain stand up pouches use puncture-resistant laminates like PET/foil for durability. Their flat-bottom gussets prevent toppling during transit. Reinforced seals withstand vibration and handling in logistics.

Q: What packaging sizes do plain stand up pouches typically offer?

A: Standard plain stand up pouches range from 4oz to 5lbs capacity. Custom dimensions accommodate snacks, grains, or powders. Side gussets allow adjustable width while maintaining vertical stability.