- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

deboss meaning

Understanding Deboss Definitions and Applications

The term deboss is often used in the fields of design, manufacturing, and crafting. To deboss means to create a depressed or recessed impression in a material. This technique contrasts with embossing, which creates a raised design. Debossing can be performed on a variety of materials including paper, leather, metal, and plastic, and it is commonly employed in various industries for both aesthetic and functional purposes.

The Debossing Process

The debossing process involves pressing a design or text into a material using a die or mold. The die is typically made of metal and is engraved with the desired design. When pressure is applied, the die pushes into the material, creating an indented effect. This process can be achieved manually with hand tools or through the use of machines in larger production settings.

There are different techniques for debossing, including blind debossing, where the design is created without any additional ink or foil, and foil debossing, where a metallic foil is used in conjunction with the debossing process for added visual appeal. The choice of technique often depends on the intended application and the desired aesthetic outcomes.

Applications of Debossing

1. Leather Goods One of the most common applications of debossing is in the creation of leather goods such as wallets, belts, and bags. A brand's logo or a custom design can be debossed onto the leather, providing a sophisticated and professional appearance. This technique is often preferred because it creates a lasting impression without compromising the integrity of the leather.

2. Stationery In the world of stationery, debossing is frequently used for business cards, invitations, and personalized stationery. The tactile experience of a debossed design adds a level of elegance and is often perceived as high-quality. It allows for a unique touch that can make a memorable impact in personal and professional communications.

deboss meaning

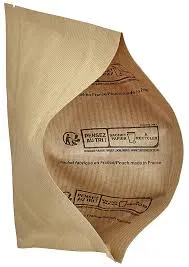

3. Packaging Debossing is also used in packaging design to enhance the visual appeal of product boxes and labels. By debossing logos or decorative elements onto packaging, brands can differentiate themselves on retail shelves and create an engaging unboxing experience for consumers.

4. Industrial Applications Beyond aesthetics, debossing can serve functional purposes in various industrial applications. For instance, debossed markings on equipment can provide information such as model numbers or safety instructions in a durable manner, ensuring that the information remains clear in environments that may wear away printed text.

The Benefits of Debossing

The technique of debossing offers several advantages. A primary benefit is its durability. Debossed designs are less likely to fade or wear off compared to printed designs, making them ideal for items that will experience wear and tear, such as leather goods and packaging.

Another benefit is the tactile quality that debossing adds. Consumers are often drawn to textures, and a debossed surface can create a sensory experience that elevates the perceived value of a product. This can enhance brand loyalty and encourage repeat purchases.

Furthermore, debossing allows for creativity and personalization. Businesses can utilize this technique to create custom designs tailored to their brand identity or consumer preferences. The capability to deboss custom logos or unique patterns means that brands can express their personality in a tangible way.

Conclusion

In conclusion, debossing is a versatile technique that has found its place in various industries, from fashion and stationery to packaging and industrial applications. Understanding the meaning and potential of debossing allows designers and manufacturers to leverage its benefits effectively. Whether for branding, aesthetics, or functionality, debossing is a valuable tool in modern design practices. As trends evolve and consumer preferences shift, the use of debossing may expand even further, continuing to leave an indelible impression on materials and products alike. With its ability to combine durability with elegance, debossing undoubtedly offers a tactile and visual appeal that is hard to overlook.