- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

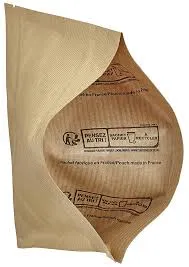

flexo print

Exploring the World of Flexo Printing A Comprehensive Overview

Flexographic printing, commonly referred to as flexo, is a versatile and efficient printing technology that has revolutionized the printing industry over the past few decades. This technique employs a unique rotary printing process that utilizes flexible relief plates, making it particularly suitable for high-speed production and a wide range of substrates. As we delve deeper into the subject, it becomes evident that flexo printing offers numerous advantages, applications, and innovations that contribute to its growing popularity.

The Principles of Flexo Printing

At its core, flexo printing relies on a simple yet effective mechanism. The process begins with the creation of flexible photopolymer plates, which are often made from rubber or photopolymer materials. These plates are engraved with the desired image or text in relief. When the plates rotate, they transfer ink onto the substrate—such as plastic, paper, or cardboard—producing high-quality prints.

Flexography utilizes a variety of inks, including water-based, solvent-based, and UV curable inks, which can cater to diverse product requirements. The adaptability of ink formulations allows printers to achieve specific properties, such as resistance to fading or moisture, further expanding the range of applications for flexo printing.

Key Advantages

One of the standout features of flexo printing is its inherent efficiency. This technique can achieve high-speed production runs, making it an ideal choice for packaging, labels, and other high-demand print applications. Additionally, the use of flexible plates allows for quick changeovers, reducing downtime between jobs and enhancing overall productivity.

Flexographic printing is also known for its ability to produce consistent, high-quality prints. The relief design of the plates ensures excellent ink transfer, which leads to sharp, clear images and vibrant colors. Furthermore, flexo printing is capable of printing on a wide variety of substrates, from traditional paper to non-absorbent materials, making it an incredibly versatile option for manufacturers.

Applications of Flexo Printing

The versatility of flexo printing has led to its adoption across various industries. Some of the most notable applications include

flexo print

1. Packaging Flexo printing plays a crucial role in the production of flexible packaging materials, such as films, bags, and pouches. Its ability to print on non-porous surfaces expands the possibilities for product presentation and branding.

2. Labels From beverage labels to food packaging, flexo printing is the go-to method for producing high-quality labels. The process allows for intricate designs and vibrant colors, ensuring that products stand out on the shelf.

3. Corrugated Cardboard Flexo printing is widely used in the production of corrugated boxes, where durability and print quality are paramount. The technology can effectively print on rough surfaces while maintaining clarity.

4. Textiles In the textile industry, flexo printing is increasingly used for fashion prints and labels, offering a wide range of colors and designs that can be produced quickly.

5. Newspapers and Magazines Certain segments of the publishing industry have also adopted flexo printing capabilities, particularly for short-run, high-quality printing requirements.

Innovations and the Future of Flexo Printing

As technology continues to advance, flexo printing is undergoing significant transformations. The integration of digital technologies is reshaping the landscape, resulting in improved efficiencies and enhanced capabilities. Innovations such as laser-engraved plates and automated set-up processes are reducing production time and costs.

Moreover, sustainability has become a driving force in the industry. Flexo printing’s compatibility with water-based inks and recycled materials provides a greener alternative compared to other printing techniques. Companies are increasingly focusing on eco-friendly practices, leading to a rise in demand for sustainable packaging solutions.

Conclusion

Flexographic printing has undoubtedly made its mark as a reliable and flexible printing solution across various sectors. With its high-speed production, versatility in applications, and continuous innovations, flexo printing is set to remain a key player in the printing industry for years to come. As manufacturers and consumers alike become more conscious of sustainability, the ability of flexo printing to adapt to eco-friendly practices further solidifies its relevance in the modern world. Whether for packaging, labels, or other printed materials, flexographic printing is an impressive blend of technology and creativity that continues to evolve, promising exciting possibilities for the future.