- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

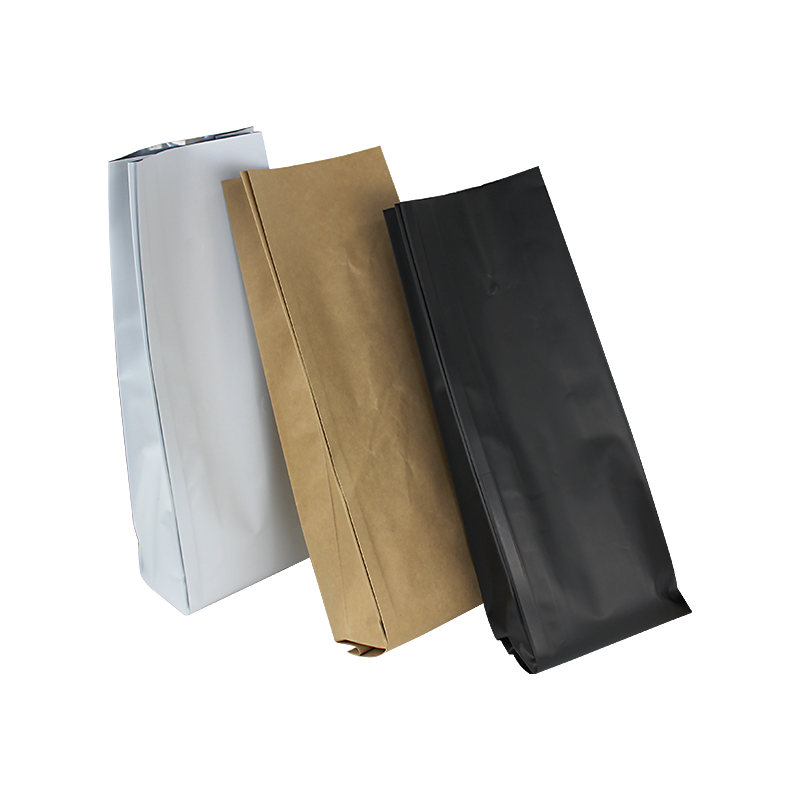

High-Quality Gusset Bag Packaging for Secure and Flexible Storage

Gusset bag packaging has become a transformative solution for industries requiring flexible, secure, and sustainable packaging. From the food and beverage sector to pharmaceuticals and industrial goods, gusset bag packaging delivers both practicality and branding power. Entering 2024, evolving consumer trends, regulatory requirements, and technological progress have only emphasized its relevance.

This article explores the latest in gusseted packaging technology—including gusseted paper bags, gusseted reclosable bags, square bottom gusseted bags, and gusseted pouch packaging—with a special focus on industry leaders like DSLPACK Established CO., LTD. For ultimate reliability and performance, DSLPACK’s signature Side Gusset Pouch Packaging Bag meets both EU and FDA standards—ensuring food safety and flexible utility.

Product Page: Side Gusset Pouch Packaging Bag

Address: No. 6 Hefu Road, Hengjiang Industrial Zone, Gaoming District, Foshan, Guangdong Province, China

Telephone: 86-133 3649 8096 Mobile: 86-757- 88811186

Email: enid@bc-pak.com

- Sustainability Drives Choice: According to the Flexible Packaging Association, sustainable gusseted paper bags and recyclable materials are now demanded by over 66% of packaging purchasers (Flexible Packaging Market Trends).

- Versatile Applications: Square bottom gusseted bags are now dominant in coffee, tea, pet food, health supplements, and industrial powders.

- Convenience and Function: Gusseted reclosable bags and side gusset pouches not only offer increased capacity but also preserve freshness, reduce waste, and improve shelf impact.

- Food Safety and Compliance: Meeting FDA/EU standards is a basic expectation. DSLPACK’s expertise in multilayer materials ensures regulatory compliance and superior barrier properties.

- Smart Packaging: Advanced printing, QR codes, degassing valves, and antimicrobial films are gaining popularity for value-added functionality.

| Item No. | Product Name | Structure | Food Grade | Valve | Suitable for | Compliance |

|---|---|---|---|---|---|---|

| 00096 | Side Gusset Pouch Packaging Bag | MOPP/VMPET/PE/AL | Yes | WIPF valve/China valve | Coffee, Other Outgassing Products | EU, FDA |

This innovative Side Gusset Pouch Packaging Bag by DSLPACK is engineered for versatility and food safety. The multilayer structure (MOPP, VMPET, PE, AL) ensures exceptional barrier protection, while multiple valve options make it ideal for coffee and other outgassing items. All raw materials are food grade and compliant with global standards—making it a premier choice among discerning businesses.

Learn More & Purchase: Side Gusset Pouch Packaging Bag Product Page

| Parameter | Description | Typical Value | Industry Range |

|---|---|---|---|

| Material Composition | Multilayer (e.g., PET/AL/PE, MOPP/VMPET/PE/AL) | MOPP/VMPET/PE | PET/PE, Paper/PE, PET/AL/PE, MOPP/VMPET/PE/AL |

| Food Grade | Compliance with FDA/EU Standards | Yes | Yes/No (most leading brands: Yes) |

| Capacity | Custom—Commonly 100g to 5kg | 250g, 500g, 1kg, 2kg | 50g–10kg |

| Closure Options | Heat seal, reclosable zipper, valve | Valve + Heat Seal | Heat Seal, Zipper, Valve, Tin Tie |

| Printing | Rotogravure/Flexo, Digital | Up to 10 colors | 1–12 colors |

| Environmental Properties | Recyclable/Biodegradable on request | Available | Standard/Available/Compostable |

- Coffee & Tea: Side gusset and square bottom bags prevent oxidation and protect flavors by integrating degassing valves.

- Snack Foods: Gusseted pouch packaging allows for expanded space for snack bars, chips, dried fruits, and confectionery.

- Pharmaceuticals & Nutraceuticals: Barrier films shield sensitive components from moisture/light; reclosable options improve end-user safety.

- Pet Food: Larger capacity, puncture-resistant bags meet consumer needs for usability and storage.

- Industrial Using: Powders, granules, technical parts are safely shipped in heavy-duty gusseted bags.

Each application requires specific customization—material structure, barrier strength, capacity, valve type—which DSLPACK Established CO., LTD. delivers with leading expertise.

- 22+ Years of Expertise: Full solution provider from design, prototyping, mass production to global logistics.

- Certified Safety: All bags made with food-grade, certified materials; rigorous QA/QC protocols for compliance worldwide.

- Customization: From farm-roasted coffee to premium snacks, DSLPACK tailors structure, valves, and print to your needs.

- Technical Support: In-house R&D, rapid prototyping, and responsive consulting—maximize packaging performance and shelf impact.

- Sustainability Commitment: Options for recyclable, compostable, and lightweight designs to support green initiatives.

- One-Stop Service: Direct manufacturer, short lead times, global reach.

Contact DSLPACK Established CO., LTD. to receive a tailored quotation or expert consultation on all gusset bag packaging applications!

- Premium Coffee Exporter (Europe): Switched to DSLPACK’s Side Gusset Pouch with WIPF valve—reduced product wastage by 18% and boosted shelf appeal, cited by Coffee&Cocoa Net.

- Snack Brand (Asia): Adopted recyclable gusseted pouch packaging and achieved double-digit growth in eco-friendly private-label sales (FPA report).

- Pet Food Processor (USA): Implemented square bottom gusseted bags with reclosable zippers, raising customer satisfaction scores by 23%—as referenced on PetfoodIndustry.com.

The ongoing evolution of gusset bag packaging—across gusseted paper bags, reclosable variants, and square bottom/side gusseted innovations—demonstrates its pivotal role in tomorrow’s packaging world. Driven by expertise, technical authority, and a commitment to safety and sustainability, DSLPACK Established CO., LTD. offers high-value, compliant solutions for every need. For sourcing, OEM/ODM, and up-to-date technical consulting, DSLPACK is your partner-of-choice.