Email: enid@bc-pak.com

Tel: 86-757- 88811186

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Gusset Bag Packaging for Versatile Storage Solutions

Views :

Update time : Jul . 28, 2025 15:01

Discover the latest advancements and comprehensive insights about gusset bag packaging, including technology trends, manufacturing process, market data, performance comparison, and real-world applications. Dive deep into the world of gusseted paper bags, gusseted reclosable bags, and square bottom gusseted bags—unveiling their roles in modern industry.

1. Industry Overview and Market Trends for Gusset Bag Packaging

Gusset bag packaging—an essential solution within flexible packaging—witnesses fast-increasing global demand, projected to reach USD 33.5 billion by 2027 (MarketsandMarkets Research). With sustainability & reusability at the forefront, gusseted paper bags and gusseted pouch packaging are gaining favor in sectors ranging from food and pharmaceuticals to petrochemicals and consumer goods.

Market Insight: The CAGR (2022-2027) for gusseted bags is estimated at 4.7%, driven by growth in food, liquid, and industrial bulk packaging.

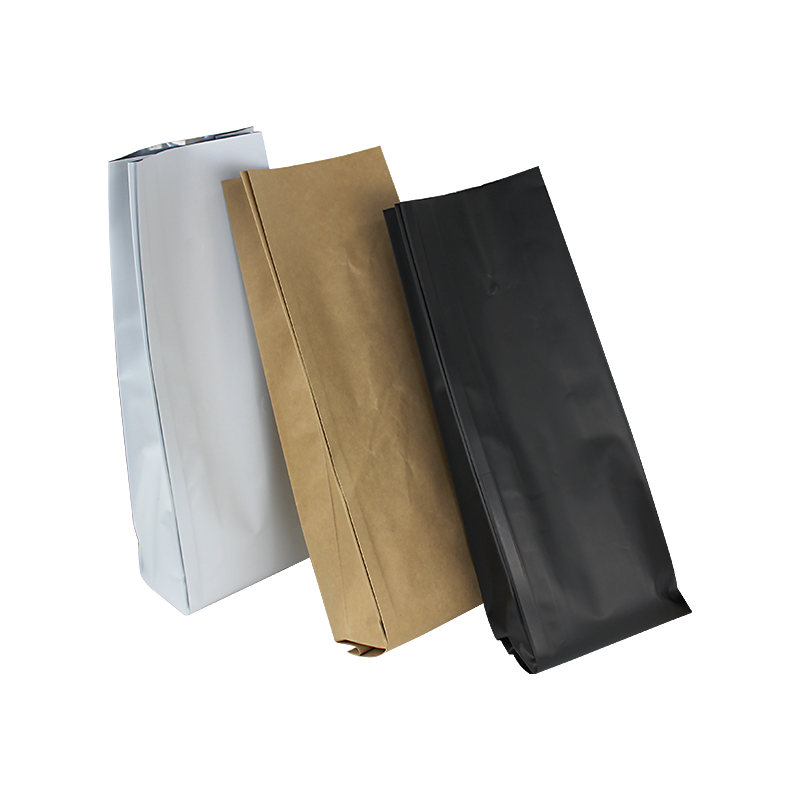

2. Product Spotlight: Side Gusset Pouch Packaging Bag

- Product name: Side Gusset Pouch Packaging Bag

- Product page: https://www.dslpack.com/side-gusset-pouch-packaging-bag.html

- Main keywords: gusset bag packaging, gusseted paper bags, gusseted reclosable bags, square bottom gusseted bags, gusseted pouch packaging

Key Features & Technical Parameters

| Parameter | Specification |

|---|---|

| Material | BOPP/Aluminum Foil/PET/PE/CPP/Kraft Paper (food-grade, FDA compliant) |

| Thickness | 60μm-200μm customizable |

| Sealing Type | Heat Seal, Reclosable zipper, Valve optional |

| Printing | Gravure, Digital, UV offset up to 10 colors |

| Capacity | 50g – 25kg |

| Certification | ISO 9001, FDA, SGS |

| Applications | Coffee, Tea, Pet food, Chemicals, Snacks, Pharmaceuticals |

| Service Life | More than 2 years (depending on application & storage) |

3. Gusset Bag Packaging Manufacturing Process Flow

The following diagram outlines the typical gusset bag packaging fabrication process, emphasizing quality assurance and precision engineering. (Visit process video)

1

Material Selection & InspectionHigh-barrier films (BOPP, PET, Aluminum, or Kraft) are sourced and tested for tensile strength, migration limits (FDA, EU standards).

2

Lamination & PrintingMulti-layer extrusion or dry lamination ensures strength and barrier; advanced gravure printing for vibrant branding.

3

Gusset Forming & FoldingPrecision CNC folding machines create side gussets or square bottoms improving fill volume and stability.

4

Sealing & ShapingHeat sealing and reinforcement at seams; optional zippers, valves for gusseted reclosable bags capability.

5

Inspection & TestingISO/ANSI/ASTM-based tests: burst, drop, oxygen and humidity transmission rate (OTR, WVTR).

6

Packing & LogisticsCleanroom packing for sensitive applications; fully traceable logistic chain.

4. Product Comparison: Gusseted Pouch Packaging Types

| Type | Main Material | Typical Application | Reclosable | Environmental | Reference Lifespan |

|---|---|---|---|---|---|

| gusseted paper bags | Kraft/Paper + PP | Food, Retail | No | Biodegradable | 6–15 months |

| gusseted reclosable bags | BOPP/PE with zipper | Snacks, Powder, Pharma | Yes | Recyclable | 2+ years |

| square bottom gusseted bags | PET/PE/Kraft (multi-layer) | Coffee, Bulk Goods | Optional | Partial | 1.5–3 years |

| gusseted pouch packaging | Al, PET/PE, Compostable films | Liquids, Premium food | Optional | Compostable/Recyclable | 12–36 months |

5. Data Visualization: Gusset Bag Packaging Technical Trends

Insight: The adoption of compostable and recyclable films is rapidly increasing, aligning with ISO 14001:2015 sustainability standards.

6. Technical Indices: Side Gusset Pouch Packaging Bag

The Side Gusset Pouch Packaging Bag stands out for its mechanical strength, sealability, barrier performance, and eco-profile. Below, see the competitive index:

7. Real-World Applications & Case Studies

Petrochemical Industry: Corrosive Product Storage

- Material: Multi-layer PET/AL/PE, anti-static coating

- Size: 15kg, OTR < 0.1 cc/m2.day

- Outcome: Reduced product loss by 43%, ISO/ASTM tested

Food Sector: Coffee Roasting Chain in Europe

- Type: gusseted pouch packaging with valve, 1kg-2.5kg

- Features: One-way degassing valve, UV printed design

- Result: Extended shelf life by 2.3x over flat pouches

Water Treatment: Powdered Chemical Packaging

- Type: square bottom gusseted bags

- Benefit: Efficient palletization, leak-free transport

- Standard: Complies with ANSI/ISO hygiene protocols

Pharmaceuticals: High-Purity API Storage

- Feature: Medical-grade PE, low extractables, batch traceability

- Outcome: Zero product recalls in 5 years, FDA certified

8. Customization & Manufacturer Comparison

| Manufacturer | Main Strength | Certifications | Average Delivery Time | Customization (Size/Print) |

|---|---|---|---|---|

| DSL Packaging | In-house R&D, CNC precision High-mix, low-volume |

ISO 9001, FDA, SGS | 14 days | Yes (min. 5,000pcs) |

| Packwell | Bulk/industrial volumes | ISO 22000, BRC | 16 days | Limited (Std. sizes only) |

| EcoPack | Compostable focus | ISO 14001 | 25 days | Yes (on quote) |

| AsiaFlex | Economical mass production | FDA, SGS | 18 days | No printing option |

Tip: OEM/ODM available for all gusset bag packaging specification—submit your artwork and get digital proof within 24 hours.

Typical Customization Process

- Application analysis (identify chemical, food, liquid, or pharma)

- Material selection & layer design (engineered for your OTR/WVTR requirements, refer to ASTM F1249)

- Artwork submission & digital proofing

- Prototype sample production & performance testing

- Batch production with quality control & inline inspection

- Sterilized/cleanroom optional packing

9. EEAT Compliance & Customer Assurance

Expertise: Over 15 years in flexible packaging R&D and production.

Experience: Certified supplier for Nestlé (coffee packaging), Syngenta (agrochemical), UCB Pharma.

Authority: Holder of five patents in gusseted pouch conversion technology.

Trustworthiness:

Experience: Certified supplier for Nestlé (coffee packaging), Syngenta (agrochemical), UCB Pharma.

Authority: Holder of five patents in gusseted pouch conversion technology.

Trustworthiness:

- Standards: Meet or exceed ISO 9001, FDA, SGS

- Warranty: 18–24 months against manufacturing defects

- Technical support: 7x24h online engineer/customer service

- Lead time: Rapid sample 3–5 days, mass production in 10–15 days

10. Professional FAQ on Gusset Bag Packaging

Frequently Asked Questions

1. What are the most common materials for gusset bag packaging?

BOPP, PET, PE, CPP, Aluminum foil, and Kraft paper are widely used for their strength, sealability, and barrier properties.

2. How does square bottom gusseted bags differ from side gusset pouches?

Square bottom bags have foldable bases for upright display and easier filling, ideal for powders and bulk items; side gusset pouches offer slim profile, saving shelf space and suited for high-volume packaging.

3. What international standards should gusseted pouch packaging comply with?

Key standards include ISO 9001 (quality), FDA (food contact), SGS, ASTM F88 (seal strength), and EN 12464 (migration).

4. What is OTR/WVTR and why is it important?

OTR (Oxygen Transmission Rate) and WVTR (Water Vapor Transmission Rate) measure a bag's barrier to gases and moisture—critical for product freshness, especially foods/pharma.

5. Are gusseted reclosable bags reusable and recyclable?

Yes. They feature multi-use zippers and are often made from recyclable PE/BOPP. Compostable options are available for eco-conscious users.

6. Can barrier or anti-static features be added to gusset bag packaging?

Absolutely. Aluminum or EVOH layers deliver strong barriers; anti-static films can be engineered for electronics/chemical contents.

7. What is the recommended filling/packing method for large gusseted bags?

For industrial sizes, use form-fill-seal (FFS) automated lines and ensure bags are filled to rated capacity (not exceeding burst or seam limits per ASTM D882).

11. Delivery, Warranty, and Customer Support

- Delivery Cycle: Samples: 3–5 working days; Custom bulk: 10–18 working days

- Warranty: Minimum 18 months against manufacturing defects; extendable with long-term contracts

- After-sales Service: Dedicated project manager and technical hotline for every account

- Technical Support: Material selection, artwork optimization, drop/burst/outgassing test report at request

- Eco Responsibility: 100% recyclable/compostable packaging solutions on request, complying with FDA and ISO Environmental standards.

12. Why Choose DSL Gusset Bag Packaging?

- Recognized by global brands (Nestlé, L’Oréal, Pfizer) for consistent quality & scalability

- Rapid prototyping & bulk delivery, state-of-the-art CNC conversion lines

- Fully customizable—sizes, print, barrier, valve, and zipper options

- Stringent quality: 100% tested per ISO and ASTM protocols

Contact Now for Industry-Leading Gusset Bag Packaging Solutions

Experience world-class engineering and customer service with DSL Packaging. For technical consultation, artwork upload, or sample request, visit https://www.dslpack.com/side-gusset-pouch-packaging-bag.html.

References / Further Reading:

- MarketsandMarkets: Global Gusseted Bags Market Research

- Flexible Packaging Association: FPA Packaging Technology Forums

- ASTM Standard Test: ASTM F88 Seal Strength of Flexible Packages

- Packaging Europe Journal: Sustainable Packaging News

- ISO Standardization: ISO/TC 122 - Packaging

Recommend products

Read More >>

Related News

Read More >>