Email: enid@bc-pak.com

Tel: 86-757- 88811186

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

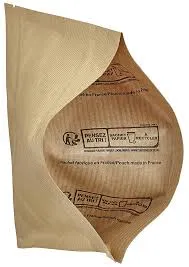

Biodegradable Pouch Bags Eco Friendly Ziplock Stand Up Food Packaging Compostable Coffee Bags

Views :

Update time : Feb . 15, 2025 15:20

The world of plastic packaging is as varied as it is vital, with numerous types of plastics serving specific functions in packaging solutions. Understanding these different types of plastics is essential for businesses aiming to optimize their packaging strategies and make informed decisions that uphold sustainability & safety, while also considering cost-efficiency. Let's delve into the most common types of plastics used in packaging, exploring their unique properties, benefits, and challenges.

Polypropylene (PP) presents a blend of strength and low-cost production, making it desirable for packaging requiring a strong physical barrier like food containers, medicine bottles, and bottle caps. PP's high melting point lends it an advantage in situations requiring sterilization conditions, crucial for medical and food-grade products. Efforts to enhance PP's recycling processes are ongoing, with increasing initiatives focusing on improving its sustainability profile, recognizing its importance amidst growing environmental considerations. Lastly, Polystyrene (PS) is widely recognized in the form of disposable utensils and expanded foam packaging. Its lightweight nature and insulation capability have secured its place in the packaging industry, although recycling remains a challenge. Companies are increasingly exploring alternatives or innovations in PS recycling to meet sustainability goals and reduce reliance on non-recyclable packaging materials. Choosing the right type of plastic for packaging involves understanding these materials' specific characteristics and weighing them against environmental, economic, and functional criteria. As businesses strive to cater to consumers’ demands for sustainable practices, it becomes increasingly crucial to align packaging choices with the principles of reduce, reuse, and recycle. Partnerships with innovative recycling firms and investing in research for developing biodegradable alternatives are pathways to contribute positively to the environment. The future of plastic packaging lies in balancing performance with sustainability, highlighting the importance of continued innovation and responsible consumption. Focusing on recyclability and investing in alternative materials can ultimately lead the packaging industry towards a more sustainable future, shaping a world where plastic continues to play an essential role, but not at the cost of our planet.

Polypropylene (PP) presents a blend of strength and low-cost production, making it desirable for packaging requiring a strong physical barrier like food containers, medicine bottles, and bottle caps. PP's high melting point lends it an advantage in situations requiring sterilization conditions, crucial for medical and food-grade products. Efforts to enhance PP's recycling processes are ongoing, with increasing initiatives focusing on improving its sustainability profile, recognizing its importance amidst growing environmental considerations. Lastly, Polystyrene (PS) is widely recognized in the form of disposable utensils and expanded foam packaging. Its lightweight nature and insulation capability have secured its place in the packaging industry, although recycling remains a challenge. Companies are increasingly exploring alternatives or innovations in PS recycling to meet sustainability goals and reduce reliance on non-recyclable packaging materials. Choosing the right type of plastic for packaging involves understanding these materials' specific characteristics and weighing them against environmental, economic, and functional criteria. As businesses strive to cater to consumers’ demands for sustainable practices, it becomes increasingly crucial to align packaging choices with the principles of reduce, reuse, and recycle. Partnerships with innovative recycling firms and investing in research for developing biodegradable alternatives are pathways to contribute positively to the environment. The future of plastic packaging lies in balancing performance with sustainability, highlighting the importance of continued innovation and responsible consumption. Focusing on recyclability and investing in alternative materials can ultimately lead the packaging industry towards a more sustainable future, shaping a world where plastic continues to play an essential role, but not at the cost of our planet.

Recommend products

Read More >>

Related News

Read More >>