- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Efficient Solutions for Uline Heat Sealers in Packaging and Preservation

Understanding Uline Heat Sealers A Comprehensive Overview

In today's fast-paced industrial landscape, efficient packaging solutions are essential for businesses aiming to streamline operations and enhance product preservation. One such solution that stands out is the Uline heat sealer, a device designed to create airtight seals on plastic packaging materials. This article delves into the significance, functionality, and advantages of Uline heat sealers for various applications.

What is a Uline Heat Sealer?

Uline is a well-known supplier of shipping, packaging, and industrial products, offering various types of heat sealers that cater to different sealing needs. A heat sealer is a machine that uses heat and pressure to bond thermoplastic materials together, creating a strong seal that keeps products fresh and secure. Uline's range of heat sealers includes manual and automatic options, accommodating businesses of various sizes and requirements.

The Mechanism Behind Heat Sealers

The basic principle behind a heat sealer is relatively simple. The device typically consists of heating elements and a pressure mechanism. When the plastic packaging is placed between the two sealing jaws, the machine activates, applying heat to melt the edges of the material. Simultaneously, pressure is applied to ensure the materials fuse effectively. Depending on the type of sealer, heat sealing can be accomplished through different methods, including impulse sealing and constant heat sealing.

Types of Uline Heat Sealers

Uline offers a diverse range of heat sealers, suitable for various applications

1. Impulse Sealers Ideal for short runs, impulse sealers are efficient and easy to use. They heat up instantly, sealing the plastic only when the foot pedal is activated, which conserves energy.

2. Constant Heat Sealers These sealers remain heated at all times, making them ideal for high-volume production environments. They can seal thicker and more challenging materials, ensuring a strong, lasting seal.

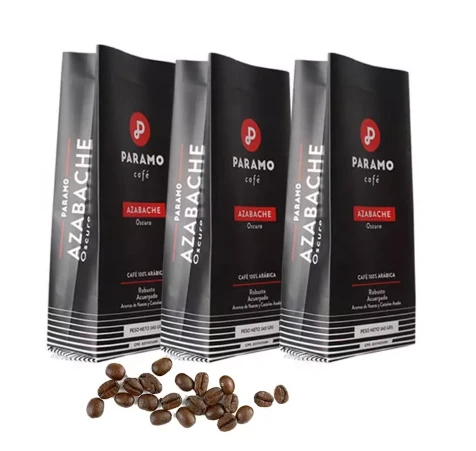

uline heat sealers

3. Handheld Sealers For businesses that require mobility and flexibility, Uline provides handheld heat sealers. These tools allow for quick, on-the-go sealing for smaller items or in locations where traditional sealers may be impractical.

Advantages of Using Uline Heat Sealers

1. Product Freshness By creating airtight seals, Uline heat sealers help preserve the freshness of food items, preventing contamination and extending shelf life.

2. Cost-Effectiveness Investing in a heat sealer can be more economical than using alternative sealing methods, such as adhesives or tapes. Heat sealing reduces material costs and labor, enhancing overall efficiency.

3. Versatility Uline heat sealers can work with various types of materials, including polyethylene and polypropylene, making them suitable for a wide range of products, from food items to medical supplies.

4. Ease of Use Most Uline heat sealers are user-friendly, requiring minimal training for staff. This simplicity allows for quick adaptation and less downtime, thus enhancing productivity.

5. Safety and Durability Uline's heat sealers are designed with safety features to protect users from burns and other hazards. Their robust construction ensures longevity, making them a reliable choice for any packing operation.

Conclusion

Uline heat sealers are integral tools for businesses that prioritize quality packaging solutions. Their ability to create strong, lasting seals not only enhances product integrity and shelf life but also streamlines the packaging process. Whether for food packaging, medical supplies, or other applications, choosing the right Uline heat sealer can significantly impact operational efficiency and product quality, making them an essential asset for modern businesses.