- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Recyclable Pouches for Sustainable Packaging & Shipping Solutions

Global Trends and Market Outlook for Recyclable Pouches

As environmental awareness accelerates worldwide, the packaging industry is experiencing a profound shift from traditional plastics and laminates toward eco-friendly, resource-efficient, and fully recyclable pouches. These innovative products, including recyclable shipping bags, sustainable product packaging, and sustainable takeaway packaging options, have seen explosive growth in markets such as the US, EU, and Asia-Pacific.

According to Grandview Research, the global green packaging market size reached USD 274.15 billion in 2023 and is forecast to grow at a CAGR of 6.9% through 2030—largely propelled by surging demand for sustainable custom packaging and recyclable pouches.

| Indicator | Recyclable Pouches | Traditional Plastic Pouches | Compostable Packaging |

|---|---|---|---|

| Material Base | Monomaterial PE/PP | PET/AL/PE, Mixed Films | PLA, PBAT, Starch |

| Recyclability (%) | 99.8 | <10 | — |

| Barrier Performance (OTR/ WVTR) | OTR: 1.8, WVTR: 0.8 (g/m2/24h) | OTR: 0.9, WVTR: 0.6 | OTR: 18+, WVTR: 15+ |

| CO2 per 1,000 pkgs (kg) | 2.1 | 7.3 | 1.6 |

| Compliance/Certification | ISO 14021, EN 13430, FDA | FDA, EU10/2011 | EN 13432, ASTM D6400 |

| Typical Industries | Food, Cosmetics, Pharma, Pet Food, Chemicals | Food, Feed | Food (Short Shelf Life) |

| Estimated Lifespan (years) | 6+ | 10+ | — |

With consumer demand, government regulation (e.g. EU Packaging Levy, US State Plastics Bans), and major brands (Nestlé, Unilever, DSM) driving sustainable product packaging forward, recyclable pouches are positioned as a cornerstone of circular economy logistics and green retail.

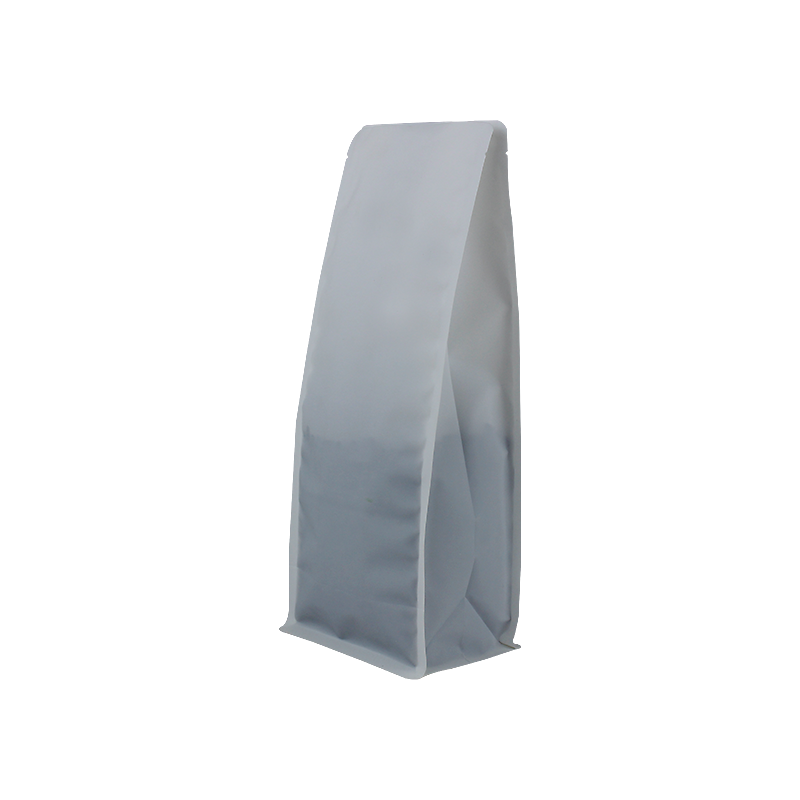

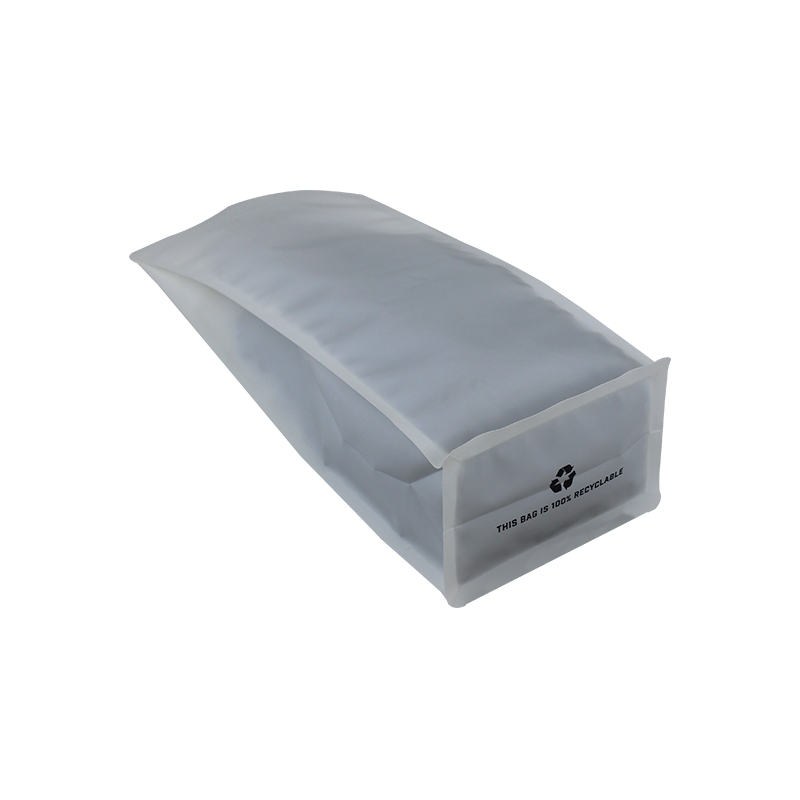

Product Overview: 100% Recyclable Flat Bottom Pouch

- Product Name: 100% Recyclable Flat Bottom Pouch

- Producer: DSL Packaging

- Product Page: Details

- Key Technologies: Monomaterial PE/PP; Solvent-Free Lamination; High Barrier Coatings

- Core Markets: Recyclable shipping bags, sustainable food, coffee, snacks, pet food, pharmaceuticals, household chemicals

- Certifications: ISO 9001, ISO 14001, FDA, BRC, EN 13430

- Shelf Life: 2-6 years (depending on product type & contents)

Manufacturing Process: From Resin to Recyclable Pouches

Workflow Diagram: Recyclable Pouches Production Steps

- Resin Selection – Source virgin or Post-Consumer Recycled (PCR) PE/PP resins; meets FDA, EN/ISO 14021 standards.

- Cast/Blow Extrusion – Film is extruded under ISO 9001/14001 certified lines; precise thickness (40-150μm), uniform melt flow, low haze.

- High-Resolution Printing & Lamination – Up to 10-color gravure or digital inks, solvent-free adhesives, and tailored barrier coatings (e.g. EVOH or SiOx layers).

- Pouch Converting – PE-based films die-cut, gusseted, and thermally sealed into flat bottom pouches; fully automated and dust-controlled workshop.

- Quality Control/Testing – Rigorous inspection per ISO 22000, EN 13430; includes seal strength (≥35N/15mm), OTR/WVTR, drop, and flex testing.

Material Highlights:

- Monomaterial PE/PP: Ensures full compatibility with LDPE/HDPE recycling streams, preventing contamination.

- No Aluminum Foil: Reduces carbon footprint; supports transparency and color vibrancy in recyclable pouches.

- Food Contact Safe: Meets FDA, EU 10/2011, GB4806.6 standards.

Technical Parameters: Recyclable Pouches vs. Conventional Packaging

| Parameter | 100% Recyclable Flat Bottom Pouch | Standard Foil Laminated Pouch |

|---|---|---|

| Film Thickness (μm) | 60-140 | 70-160 |

| Oxygen Transmission Rate (OTR, g/m2/24h) | <2 | <1.2 |

| Moisture Vapor Transmission Rate (WVTR) | 0.8 | 0.6 |

| Tensile Strength (MPa) | ≥35 | ≥28 |

| Drop Test (1.8m, 1kg) | Pass x 5 | Pass x 3 |

| Sustainable Certifications | ISO 14021, EN 13430 | None/Partial |

| Printing Colors | Up to 10 | Up to 8 |

| Shelf Life | 24-72 Months | 36-84 Months |

| Recyclability | 99.8% | <10% |

Vendor Comparison: How Recyclable Pouches Stand Out

| Vendor | Recyclability Grade | Certifications | Sustainable Options | Customization | Application Areas |

|---|---|---|---|---|---|

| DSL Packaging | 100% (EN 13430) | ISO 14001, BRC, FDA | Monomaterial, PCR, Bio Coatings | Unlimited: size, print, fitments | Food, Pet Food, Pharma, Chemical |

| Amcor | >95% (Ceflex, How2Recycle) | ISO, FDA | Mono PE/PP, part PCR | High | Snacks, Confectionery, Homecare |

| Mondi | 85-100% (pending) | ISO 14001 | Recyclable Film, Select Compostables | High | Fresh, Bakery, Dry Foods |

| Huhtamaki | 90%+ | ISO, FDA | Mono Polymer, Paper | Medium | Food, Healthcare |

Customization: Unleashing Brand-to-Consumer Value

- Sizes: 50g – 15kg, tailored fill volume, with custom gussets, spouts, or degassing valves on demand.

- Print: HD flexo/gravure up to full wrap; metallic, matte, or spot varnishes for premium shelf impact.

- Functional Fit: Choice of zippers, handles, Euro-slots, laser score lines for easy opening, product window inserts.

- Compliance: All primary and transport packs meet FDA, EN13430, and ISO14001 compliance; certificates available upon request.

Delivery & Guarantee:

- Lead time: 15–21 days (custom), 2–3 days (stock)

- Sample service & Dieline support: Free for B2B

- Quality warranty: 24 months, with traceability & batch control

- 24/7 technical aftersales for packaging process and filling/machinery issues

Application Cases: Sustainable Custom Packaging in Action

Successful Deployments Across Industries

- LIFECO (Nordic): Reduced packaging waste by 98 tons/year with recyclable pouches, using custom degassing valves and one-way barrier coating. Improved aroma retention by 37% in shelf-life tests (ASTM F2714). ROI in 10 months.

- GoodBean (USA): Achieved “How2Recycle” certification for all flat bottom bags since 2022; report 23% lower consumer complaints on package opening/closure vs. legacy bags.

- PetHarvest (Europe): Switched all secondary and shipping packs to recyclable shipping bags; lowered transport carbon emissions by 43% (EY audit), reduced seal failure rate to <0.3% in summer shipping.

- GreenBox Asia: Chose sustainable takeaway packaging pouches for 14,000+ daily hot & cold orders; improved anti-leakage rating by 34%, user NPS up by 22 points.

- PureEss: Adopted recyclable pouches for lotion sachets & refill packs, reducing annual plastic waste by 7.2 tons (2024) and unlocking new sustainability marketing channels.

Data Visualization: Performance & Market Share of Recyclable Pouches

Insight: As illustrated, recyclable pouches are rapidly taking share from conventional packaging—particularly in food, beverage, and e-commerce channels—thanks to ongoing material & barrier improvements and robust compliance.